How Aluminum Castings Company can Save You Time, Stress, and Money.

Table of Contents6 Easy Facts About Aluminum Castings Company DescribedA Biased View of Aluminum Castings CompanyThe Aluminum Castings Company Diaries8 Easy Facts About Aluminum Castings Company Shown9 Easy Facts About Aluminum Castings Company ExplainedA Biased View of Aluminum Castings CompanyThe 20-Second Trick For Aluminum Castings CompanyHow Aluminum Castings Company can Save You Time, Stress, and Money.Some Ideas on Aluminum Castings Company You Should Know

Once again, you're going to desire to locate a spreading shop that has actually done this in the past. Stratasys (or whatever maker you're utilizing) can most likely provide you some references. FDM surface area top quality is quite much from mirrorlike- you'll desire to smooth it out as much as possible prior to casting. It's a great deal simpler to sand abdominal muscle than aluminum.

Have a look over right here Detailed, patient-specific anatomic design service from 3D Equipments accuracy healthcare remedies They state Castform or thermojet Wax Patterns 3D Solution has the largest portfolio of 3D Printers. We provide 3D Printing options for production, prototyping, spreading, dental and much more. If you're in the United States you may wish to call these people: They are a prototype vendror based in Seattle and supply a service called Quickcast.

The Definitive Guide to Aluminum Castings Company

visited moeller a couple weeks ago on a trip. I've never ever worked with them nevertheless, yet heard some frightening things. heres the steez on their quickcastits a lighter RP part that has a honeycomblike interior allows the exhaustion to properly happen and is less expensive than routine SLA part. This process is commonly used for HIGH resistance components to be cast in Titanium for like airplane things.

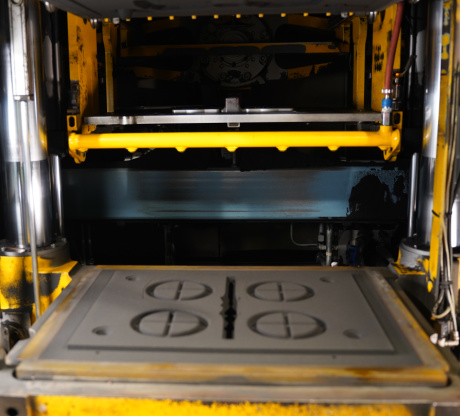

i have done some sand spreading of aluminum and it's most likely a great way to go, like everybody else has claimed, depending upon the moment you agree to take into the component after the spreading is complete - Sand Mold. you can, nevertheless make use of an RP component as a pattern for sand casting Terrific details! I may still speak to Moeller - I would certainly like to ultimately try a tiny run of vessels and the much less job I need to to postcast, the much better

Not known Incorrect Statements About Aluminum Castings Company

Machined to resistances with a second operation like string cutting and dealing with. Steel casting like injection molding uses a sprue and gate system for mold and mildew flow however can accommodate a much greater variation in wall surface density. Ceramic covering financial investment process requires no draft angles as the part is damaged out of the ceramic as a one-off waste mold.

If threads constantly need to be machined after casting this is mosting likely to be a little bit above spending plan. I hear some factories can function with close resistances up to concerning +/ -0.010 in/in.

The majority of light weight aluminum founders will certainly place on a big tune and dance number about helping you select from the countless alloys that are readily available. They will certainly after that medically get here at the very best alloy and mood choice for your certain application. It constantly transforms out to be 356-T6.;--RRB-;-- Shed foam is particularly proficient at challenging parts, where it would certainly be difficult to get rid of the pattern from the mold.

Aluminum Castings Company for Beginners

We only have the 2 places and the company specializes in Light weight aluminum Pass away Casting. The company that used to own the US operation is no much longer, and was gotten by the Italian company a little over a year earlier.

Everything about Aluminum Castings Company

Given that this is such a tiny firm, and has yet to clean up the mess from the prior owner, I are in charge of 45 employees and 38 makers on my 2 changes (2nd and Third Changes). Being liable for so much was not something I had anticipated, however I've made it my passion to produce a smooth procedure for my firm.

We have numerous inherited problems, the most significant of which is our Great deal Traceability - https://calendly.com/kelliphillips61401-proton/30min. and this is where I need all of the assistance and guidance I can obtain. The system embeded in area is made use of to trace the quality of 35 various items for various vehicle companies. About half of our products are casted internal and machined in my side of the plant

Some Known Details About Aluminum Castings Company

We check here have numerous issues in our casting division, and its constantly boosting. The light weight aluminum blocks give very couple of issues and are less complicated to control, but we still have our concerns from time to time. Our lot tracing methods seem extremely primitive, a literal tag (printed sheet of paper) that physically complies with the parts.

We have won 14 new contracts in the last 4 months, and new production is starting within a year. We need to be able to tighten it down to the shift at a minimum. Ideally the time, operator, machine, component #, batch #, quantity.

The same system has actually to be made use of for all stages of manufacturing: Casting, Trimming, Shot Blasting, Machining, et all. I am an outright newbie with this side of service, and have actually constantly stayed concentrated on keeping CNC equipments, creating programs and leading jobs. Any kind of and all assistance would certainly be substantially valued.

How Aluminum Castings Company can Save You Time, Stress, and Money.

It's certainly a subject I have actually thought about in detail and have had the benefit of having buddies that were specialist foundrymen and ability to observe their techniques (Sand Molding). There definitely is no factor that market ideal practice can not be achieved by a hobbysist, but whether that is useful or otherwise because setup may be one more issue

You can make and test all the sample vouchers you like, yet that doesn't indicate your spreadings will uniformly display the very same high qualities. Frequently times, the design attributes of a casting will indicate that it will not freeze evenly or in a directionally constant way (thick sections/intersections for instance), and those areas are the ones probably to show H2 porosity and related shrink defects and seasoned foundrymen go right to them when they section and analyze the casting.

Aluminum Castings Company Can Be Fun For Everyone

You should do the computation yet you will certainly be shocked at that mass of water. Industrial foundries will certainly purge and blanket the thaw in a holding heating system just to stop H2 infiltration when there is no flow! I make use of a resisting electric furnace since it has no air circulation. Actually, for factors I'm not quite certain, it seems to have much less than atmospheric degrees of O2, because if I thaw scrap and lift the cover, it will often blink when exposed to air.

What Does Aluminum Castings Company Mean?

If you have a fuel discharged furnace, crucible hat and cleanup gas may aid, yet can additionally be cumbersome. I'm a shed foam wheel and my mold media is dry sand. I don't need to control or fret about the moisture or various other binder web content, since it's not there. Regarding shed foam being more prone to problems and porosity, I 'd say that has not been my experienec, at the very least no even more or much less than traditional sand casting.